Honda 2005 CBR-600RR

November 17, 2005

Buttonwillow California

The 600cc sportbike market is a complicated poker game involving advanced engineering, vendor relationships and the all important price point. This is complicated by the long lead time the manufacturers require to bring a new model to market. Company Y, for instance, cannot just look at the model that Company H is selling currently, they need to forecast what Company H will be bringing to market in two years, and then try to top that forecasted model. But Company Y does not want to be too far ahead of Company H because the technology is expensive to develop and, potentially, even more expensive to produce. Company Y, therefore, aims to top Company H’s offering by the smallest possible margin of weight, horsepower and the all-important sub-component specifications.

From the right side

Further complicating this dynamic is the cap of price point. Any of the companies could be producing 135bhp 600s at 325 pounds but said 600 would cost say, with current technology, $19,000. But the OEs know that most customers will only pay, for all intents and purposes, about $8,400. From a street rider’s perspective the bikes are virtually interchangeable so one manufacturer can only raise the price of a 600 if the others will go along with the price hike, or the components on the bike are of tangibly higher value, or watch customers slowly drift off to other brands.

Although the companies build their own frames and engines, other vendors build many of the subcomponents of the motorcycles. Brakes, forks, wheels, fuel injectors, engine control systems and even internal engine parts are all sourced from other companies. These vendors have a range of products from which the manufacturers can choose; a range of forks, a range of calipers, a range of wheels etc. Of course, the top of the line equipment is too expensive (think GP or superbike forks or calipers) and the bottom of the line equipment has insufficient performance (think commuter bikes). The manufacturers need to spend as little as possible on the sub-components in order to be able to still have a profit at the aforementioned price point. Keeping that in mind, these are not the best 600s the companies can produce, they are the best 600s they can produce at this price.

But when one company shaves some cost from another aspect of the engineering or manufacturing costs and is therefore able to increase the specification of forks or brakes, it forces the other companies to respond in kind or watch their bikes grow stale. The stakes are pretty high. The US 600cc market has more than doubled from 1998 to 2004 with about 55,000 units sold each year. At full retail that means the 600cc sportbike market is worth, in gross, about $453 million dollars a year. Followers of the sportbike industry have noticed the two-year / four-year design dynamic. With rare exception the model release cycle follows a set pattern of major revisions (usually a new model) every four years with minor revisions every two years.

Honda released their new model in 2003 and the initial reports (mostly released by Honda) was that this bike was to dominate the 600 sector with its performance. In reality it has turned out that Honda had misjudged what the other companies were going to release and the CBR came to market over-weight, over-priced and under-performing.

Honda does not like to lose. The 2005 CBR600RR is the two year revision for the CBR but Honda has invested substantially more into this redesign than usual. Honda has redesigned the frame and swingarm (not cheap revisions) to drop some of the weight off the portly CBR, redesigned the bodywork to make the bike look lighter (not a cheap revision), and specified a higher grade of front suspension and brakes (not a cheap revision) and have not raised the (already high) price, all in an attempt to close the gap to the GSX-R and the R6.

Visually lighter front end with revised headlights

Roadracing World was invited to test the extensively revised CBR at Buttonwillow Raceway in California. On the eve of the test a heavy fog rolled into the San Joaquin Valley and settled comfortably on the racetrack. The fog soaked the racetrack and obscured the sun. The test day, therefore, consisted of riding on a patchy drying track on the stock Dunlop 218 tires in the misty morning and riding on Dunlop 208 GP DOT race tires on a mostly dry track in the afternoon beneath a heavily overcast sky. These circumstances gave great consternation to the photographers and the sponsors of the day’s events but offered an excellent opportunity to really sample the bike’s feel in these tricky conditions.

Heated pillion seat.

The first two sessions involved a somewhat dry line around roughly half of the track with the remaining 50% of pavement ranging from damp to wet; the kind of conditions that give racers and crew chiefs ulcers and convert tire men into weather forecasters as everyone struggles to pick the right tire. As far as OE fitment goes, it seemed Honda had chosen the correct fitment. The 218s offered surprising grip on the damp, and even wet, surface and the new front end on the Honda kept me informed as to exactly how much traction I had. Although the track temperature was low the front tire was able to handle off throttle sweepers across damp pavement without even the tell tale oscillation usually felt in reduced traction conditions. When crossing the slippery sealant strips the revised fork transmitted the temporary loss of traction straight to my hands.

Centrally mounted gas tank, Unit Pro-Link suspension.

Accelerating out of slow second gear turns on a damp track on a powerful motorcycle can make for some interesting moments. Not only was the 218 tire up to the task, but the engine’s perfectly linear throttle pick-up allowed for surprisingly aggressive corner exits even on the damp sections of the track. The engine has a smooth usable midrange that builds to a nice top end. The top end hit is not as pronounced as on some 600s but this is probably due to the fact that the midrange is more filled out so the top end rush is more muted. Future dyno runs will investigate this hypothesis. The whole bike felt so tight and predictable that it was easy to concentrate on the tricky conditions without worrying that the bike was going to do something surprising.

The CBR has a short tank that places the rider further forward over the instruments than on many other 600s. I initially found this to be disconcerting because it can get crowded between the padding in the elbows of the leathers and the knee armor, and it also gives me a little bit of a Superman feeling of flying through the air in front of, instead of behind, the front axle. After a few laps of acclimation I began scooting back on the seat to create some tuck in room on the straight, scooting back a lot when on the brakes to keep the rear settled and then moving all the way forward to weight the front end mid-corner.

New chain adjusters, beautiful internal braced welding.

The CBR’s shifting is very precise with low effort, and the bike speed shifts with just the slightest easing of the throttle. The clutch was low effort with a nice feel and linear action. In the afternoon Dunlop installed D208GP DOT race tires. With the improved traction conditions and the improved grip from the race rubber it was possible to tax the new chassis, front end and brakes. This was my first time riding on this portion of Buttonwillow. The track surface is pretty decent but there are numerous seams, undulations, bumps, assorted potholes and a particularly treacherous crest leading onto a sealant covered downhill left turn. As I hunted for good lines through these turns I ran across most of the bumps and ruts and had ample opportunities to sample the slippery sealant covering all but the most of inside lines through that cresting turn, and the CBR handled it all.

This is not to say that the bike wouldn’t slither across the sealant or bump and jar across the holes and ruts, however, the bike would recover quickly from harsh inputs and continue to track where I wanted it to go. It would take a big hit to the front end, the handle bars would twist in my hands, then it would just settle and keep arcing through the corner. I’d miss my apex for the blind turn, cross out onto the sealant, the bike would get all slithery and loose, then I could just pick it back up on the throttle and hit the exit. It wouldn’t headshake, it gave good mid-corner feel and it didn’t seem to run wide on exits.

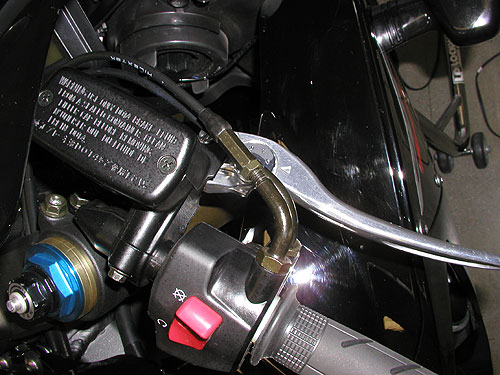

The brakes are improved over the old model both in terms of lighter effort and more predictable behavior. Honda cheaped out on the master cylinder using a conventional master cylinder instead of the sexier and more powerful radial master cylinder but the new calipers and pads are a big improvement over the ‘03. Testing the 2003 CBR I lost all braking for one corner when the pads backed away from the rotors. This year, even on a much bumpier track with more aggressive riding, there was no hint of such a failure.

Still using the old school master cylinder.

Radial mount calipers and 41mm inverted fork. Tire warmer is optional.

The three biggest gripes I had with the 2003 model were a dead feeling front end, so-so brakes and too much weight. The 2005 model has the best front end I’ve felt on a Honda (not just their 600s either) and improved brakes in a lighter weight package.

The last dynamic here is price. The CBR is the most expensive 600 in this category and still weighs two pounds more than the GSX-R 750. Honda loyalists will love this bike but I think the racer market and non-brand loyalist street/track day riders still might not see performance value for the extra cost.

A full comparison test coming up soon will resolve that for certain.

Less is More

The biggest complaint about the 2003 CBR600RR was weight, and in response, Honda lightened the 2005 CBR by nine pounds. The frame, swingarm and exhaust have all slimmed down. The frame’s spars are cast with thinner sides (-0.2mm) and thinner tops and bottoms (-0.5mm). The reduced material has lightened the frame by 3.6 pounds while revisions to the swingarm including a cast top shock mount instead of the bolted piece (along with some slight styling changes) have shaved 4.4 ounces. The underseat exhaust lost 20.6 ounces from the system even with the addition of a new catalytic converter.

New cast top shock mount instead of the original bolted on mount.

Note, this is the spot on most bikes where the shock is bolted to the frame.

Weight was also removed from the instrument panel, axles, seat assembly, side stand bracket, drive sprocket, clip-ons and the footpeg brackets. The heels guards are so thin and light that after being easily deformed by the rider’s heels during track riding they can be straightened by hand. Bolted to the front of the new frame are the now class ubiquitous 41mm inverted front forks with Tokico radial mounted brake calipers. The forks are very nice and the radial mounted calipers are a marked improvement over last year’s brakes. The rear suspension is the mildly controversial Unit Pro-link that is purported to isolate more of the rear suspension movement and energy from the frame.

Lighter instrument cluster.

The engine has a number of internal revisions. The pistons are now treated with molybdenum to reduce internal friction and they run in coated low friction aluminum cylinder liners. The intake ports have been revised to boost mid-range power. The 2005 retains the sassy dual injector per cylinder set-up (one in the throttle body, one shower injector in the air box lid) but is fitted with new injectors for faster fuel flow. These refinements are intended to increase mid-range power and torque.

Lighter exhaust pipe and muffler snaking its way through the undercarriage.

Honda has given the freshened up CBR a mild cosmetic make over as well. The tailsection has been tweaked and the front fairing has less prominent air intakes for the fresh air induction system. The headlights have been slightly changed as well.

The 2005 Honda CBR600RR is available in black, black with gray flames, red or silver for $8,799.